Metal Stamping Innovations: Elevating Manufacturing Processes for Superior Outcomes

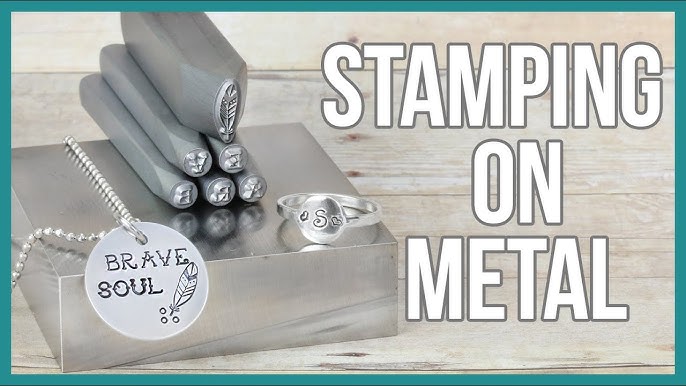

In the realm of making processes, steel marking has long been a keystone technique for producing a range of accuracy parts. With the unrelenting march of technological development, the landscape of metal stamping is undertaking a significant transformation.

Development of Metal Marking Techniques

Additionally, advancements in product science have actually brought about the advancement of high-strength alloys that can currently be effortlessly stamped into intricate forms, satisfying a more comprehensive variety of commercial applications. The integration of robotics and synthetic intelligence has even more enhanced the stamping procedure by improving rate and precision while reducing the threat of human mistake.

Effect of Advanced Products

Have advanced materials changed steel marking processes substantially in the production market? The response is an unquestionable yes (Metal Stamping). The assimilation of innovative products has actually transformed steel marking, allowing producers to attain greater precision, increased effectiveness, and boosted product top quality. By using materials such as high-strength alloys, progressed composites, and innovative coatings, steel stamping procedures can now generate elements that are lighter, stronger, and extra long lasting than ever previously.

These innovative products use remarkable mechanical properties, deterioration resistance, and thermal security, enabling producers to meet the demands of contemporary sectors such as aerospace, vehicle, and electronics. In addition, making use of sophisticated materials in metal stamping has actually assisted in the production of intricate geometries and intricate styles that were previously unattainable via traditional methods.

Additionally, the application of innovative products has actually caused lowered product waste, lower production costs, and shorter preparations, making steel stamping processes much more economical and lasting. As modern technology remains to advancement, the impact of innovative products on metal stamping processes is expected to drive further innovation and enhance the competitiveness of suppliers in the worldwide market.

Automation in Metal Stamping

The evolution of metal marking processes driven by the assimilation of sophisticated materials has actually set the stage for considerable advancements in automation within the manufacturing market. Automation in steel stamping has changed manufacturing processes, boosting efficiency, accuracy, and general output top quality. With the usage of robotics, sensing units, and computer-controlled systems, jobs that were time-consuming and as soon as hands-on can now be executed with exceptional speed and precision.

Automation in metal marking not just accelerates production rates but also guarantees consistency in the manufacturing process. By reducing human intervention, the risk of errors is considerably decreased, resulting in greater levels of product uniformity and integrity. Furthermore, automation allows producers to take on intricate marking jobs that would be unwise or challenging to attain manually.

In addition, automation in steel stamping adds to a safer working atmosphere by decreasing the demand for workers to take part in repeated or unsafe jobs - Metal Stamping. This shift towards automation not only enhances efficiency however likewise paves the way for the future of production, where modern technology plays a main role in driving functional quality

Top Quality Control and Evaluation Solutions

With a focus on precision and dependability, top quality control and inspection systems play an essential role in making sure item quality in steel marking procedures. These systems are made to check every phase of production, from material evaluation to the last item, to assure that all wikipedia reference parts meet the needed criteria. By implementing sophisticated modern technologies such as optical evaluation systems, coordinate gauging devices (CMM), and automated determining devices, manufacturers can identify even the tiniest deviations in dimensions, surface high quality, and overall stability of stamped components.

Sustainability Practices in Steel Stamping

Structure upon the structure of accuracy and reliability established through quality control and examination systems, the combination of lasting methods in steel stamping procedures is significantly becoming a focal point for manufacturers seeking to decrease environmental effect and optimize source utilization. Sustainability methods in steel stamping include a variety of campaigns intended at reducing waste generation, power consumption, and greenhouse gas exhausts throughout the production process.

One key element of sustainability in metal stamping is the fostering of environment-friendly products and modern technologies that advertise recyclability and waste reduction. By utilizing recycled materials and carrying out energy-efficient machinery, manufacturers can decrease their carbon impact and contribute to a more lasting manufacturing cycle. In addition, maximizing manufacturing processes to decrease product waste and energy use not just profits the environment however likewise results in cost savings for organizations in the future.

Additionally, the application of sustainable practices in metal marking can boost brand name online reputation and attract environmentally aware consumers. As sustainability remains to acquire value in the production industry, integrating green campaigns into steel marking processes is crucial for long-term success and competition on the market.

Verdict

Finally, metal marking strategies have dramatically developed with time, incorporating sophisticated products and automation to boost manufacturing processes. Quality assurance and assessment systems play an essential duty in making sure superior outcomes, while sustainability techniques are progressively my company being implemented to decrease ecological effect. These developments in steel stamping have actually changed the market, causing a lot more effective and lasting production techniques for numerous sectors.

Steel marking, as soon as a manual and labor-intensive process, has transformed into a very automated and innovative method of shaping metal sheets into numerous kinds and styles.Have sophisticated products changed steel stamping processes dramatically in the manufacturing sector? By using products such as high-strength alloys, advanced composites, and ingenious coverings, steel marking procedures can now generate parts that are lighter, stronger, and a lot more sturdy than ever in the past.

The development of metal marking procedures driven by the integration of innovative materials has actually established the stage for substantial developments in automation within the production sector.In conclusion, metal marking techniques have actually significantly advanced over time, including advanced materials and automation to improve producing processes.